Titanium metal foam may help fuse metal into bones to repair damages

27 Dec 2014

A new metallic foam made of titanium would now make fusion of metals to repair broken bones possible. The titanium foam opens the possibility of using malleable yet strong metal foams instead of hard metal to repair damaged bones.

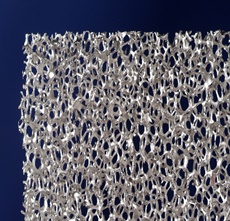

The titanium foam is made by saturating a polyurethane solution with a solution of titanium powder and binding agents. The metal powder assumes the shape of the resultant foam and by evaporating the foam a titanium lattice in the shape of the original foam is obtained. This can then be heat-treated to regain titanium's metal properties. The resultant is a porus metallic foam that is softer but strong, although the exact properties of the foam would depend on its porosity.

The titanium foam is made by saturating a polyurethane solution with a solution of titanium powder and binding agents. The metal powder assumes the shape of the resultant foam and by evaporating the foam a titanium lattice in the shape of the original foam is obtained. This can then be heat-treated to regain titanium's metal properties. The resultant is a porus metallic foam that is softer but strong, although the exact properties of the foam would depend on its porosity.

However, the titanium foam thus obtained is strong and light enough for replacing bones – while it retains the mechanical properties of titanium metal its porosity would allow new bone to grow in and around its structure, thus integrating the implant within the skeleton.

Doctors now use titanium alloy for bone implants. While these are well tolerated by the body, the rigidity of the metal leaves much to be desired in a growing bone, especially when the patient is young and growing.

Also, the mass of the metal and bones rarely match as they implants are typically made of solid metal – usually titanium that is significantly stiffer than bone. This means that an implant may leave a far higher load than the bone it is expected to bind.

The mismatch and the stress of the metal on the bone would result in the deterioration of the bone and loosening of the implant, necessitating replacement of the metal.

Peter Quadbeck and his colleagues at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials Research in Dresden, Germany, have created a titanium implant with a foam-like structure, inspired by the spongy nature of bone. The titanium foam does a better job than solid metal when it comes to matching the mechanical properties of bone, such as flexibility, and this encourages more effective bone regrowth.

What's more, the foam is porous, so the bone can grow around and within it, truly integrating the implant with the skeleton.

Though the foam has yet to be approved for use in humans, Quadbeck and colleagues are now working with physicians to explore its suitability for treating certain injuries.

Peter Lee of the Department of Materials at Imperial College London says there are applications where inserting one of these titanium foams "looks like the most promising solution", such as bridging long gaps between broken bones.

Yuyuan Zhao, a materials engineer at the University of Liverpool, UK, adds that "if human bone isn't good enough, an implant could give your body better performance" than leaving bone to heal naturally or using other types of implant.